Of course, you could adapt this idea for a much smaller area and use it to store garden chairs, garden tools, other random bits and bobs too – which I kind of wish we’d added a separate space to do too. This meant we needed to remove the sloping slabs near the conservatory and shift some sand/rubble beneath it so that the ground would be lowered enough, to provide a seamless step from the conservatory onto the decking, rather than a step-up. We’re building ours as a mixture of both – slightly raised at the front, but sat onto the ground at the back (ever awkward here). The easier option is building it straight onto the ground, and for this, you would need to level the ground first.

Depending on how high you want your decking to be, and whether the ground is sloped or not, will usually depend on which route you take. There are two main types of decking, one that sits straight onto the ground, the other is raised. So if you’re interested in finding out how it’s all built and how much it cost, then here’s all in the info you need. And less wood all round means less money. They’re also much thicker, which meant we could get away with using less wood within the frame. Used scaffold boards are much cheaper priced per meter, and they’re much wider too which would mean we would need fewer boards. With value decking boards costing upwards of £5 for a 2.4m length, my calculations led to me to believe we’d be spending considerable 3-figures on the amount we would need. So why scaffold boards over normal decking boards, you ask? Well, cost played the most important role here. You guys know I’m all about that storage space! It seemed like a win-win, so we went ahead with it. I also quite like decking for its modern look and I also planned to use the space underneath the decking as storage too. And not to mention, it would hide the unsightly drain cover too, but still, give us access in the future. The step issue, in particular, is one of the main reasons decking appealed to me, as it meant we could easily raise the deck up to provide an almost seamless transition between the inside floor and outside floor. And on top of that, there’s a drain cover right beneath the door, which meant we couldn’t build a step there. The step into the kitchen (through the french doors) was also a little over 1ft high which our eldest dog was struggling to use. Needless to say, it didn’t look very appealing. Continue reading “Tube chair with a frame made from scaffold tubes – adjustable inclination for the backrest.” Hallway coat hanger and wardrobe made from scaffold pipes and reclaimed wood.#GardenGoals right? We had sloped paving slabs in front of the conservatory, then a large L-shaped area of concrete and a small section of soil in front of that – It was basically a mishmash of everything and anything.

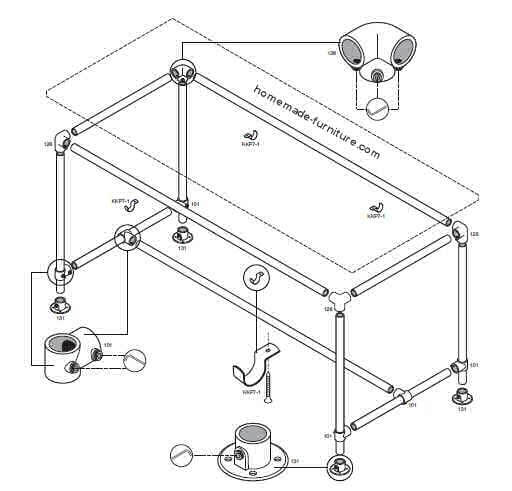

Nevertheless we advise to spend some time on a nice finish.Ĭhoose nice looking planks, and sand them as smooth as possible before you aooly a woodstain to the planks. This wood is lightly preserved and could even be used without any woodstain. Therefore it has a weathered look and feel to it. This wood has been outside for several years. Simply dismantle and recycle them in another furniture project. You can repurpose the tube chair parts if you are not happy with the result. Steel tubes and pipe clamps in combination with thick wood from the same scaffold. Weatherproof furniture, made with materials from reclaimed scaffolding. Exploded view construction drawing for a tube chair.Ĭhairs for inside or to use in the garden. scaffold tubes and Kee clamps.Ĭonstruction drawings to make a tube chair from scaffolding pipes.

Reclaimed pallets can be easily converted into chairs or tables. Easy examples to make furniture at home with just a few basic tools.

0 kommentar(er)

0 kommentar(er)